Heat mixture over the conversion range, hold it at this temperature, and then cool the air at a temperature below the conversion range. This results in relief from stress, increased energy, and increased stiffness. This process is also used in products designed to improve grain composition, improve efficiency, and improve response to subsequent heat treatment processes.

Case hardening / Carburizing is a process used to reinforce the outer layer of metal reinforcing steel while keeping the inner metalcore soft. The case-by-case process uses a combination of charges to make more carbon. The depth of the steel plate depends on the use of the depth of the solid sides.

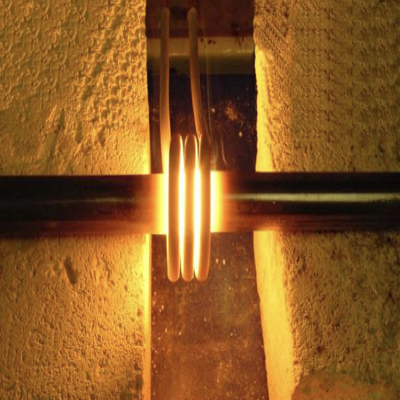

Induction Hardening Induction stiffness is a form of heat treatment in which part of the metal is heated to induction heat and then extinguished. Extinguished metal undergoes martensitic changes, which increase the stiffness and stiffness of the part. Induction reinforcement is used to specifically tighten parts of a part or assembly without affecting the parts of the whole part.

The process of heat treatment in which the metal is heated to a temperature below the conversion range, which is stored for the right time, and then cooled. The result is a decrease in complexity and an increase in complexity.

Annealing is a heat treatment process that changes the structure of small objects to change its mechanical or electrical properties. Often, in steels, adhesives are used to reduce stiffness, increase ductility and help eliminate internal pressures.

Pressure reductions are performed on steel products to reduce residual pressures in the structure thereby reducing the risk of size changes during continuous manufacturing or final use of the component.

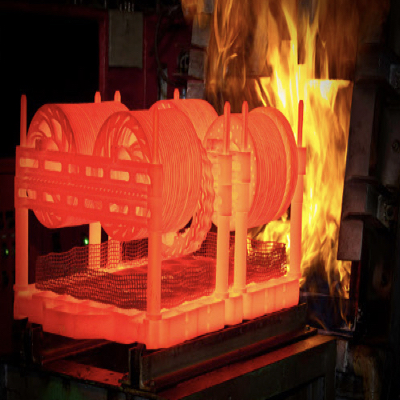

Salt Bath Hardening can provide benefits in addition to different methods of durability and durability. Soluble salt is often considered a ‘proper’ remedy for heat treatment.

492, GIDC, Makarpura Industries Estate, Vadodara - 390010

shriramvajra492@gmail.com info@shriramvajra.in

9825-949-815

© Copyright 2021, All Rights Reserved, iweb wala